In-wheel motor- What do you know?

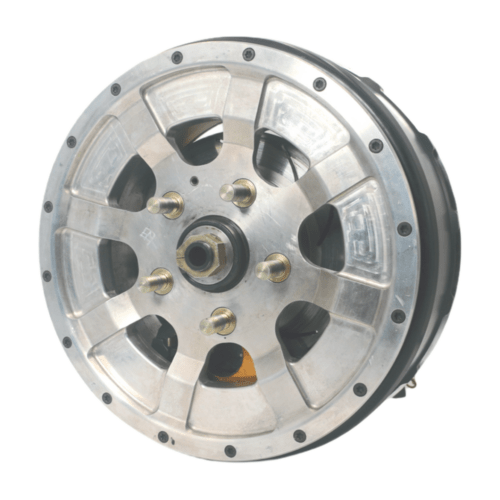

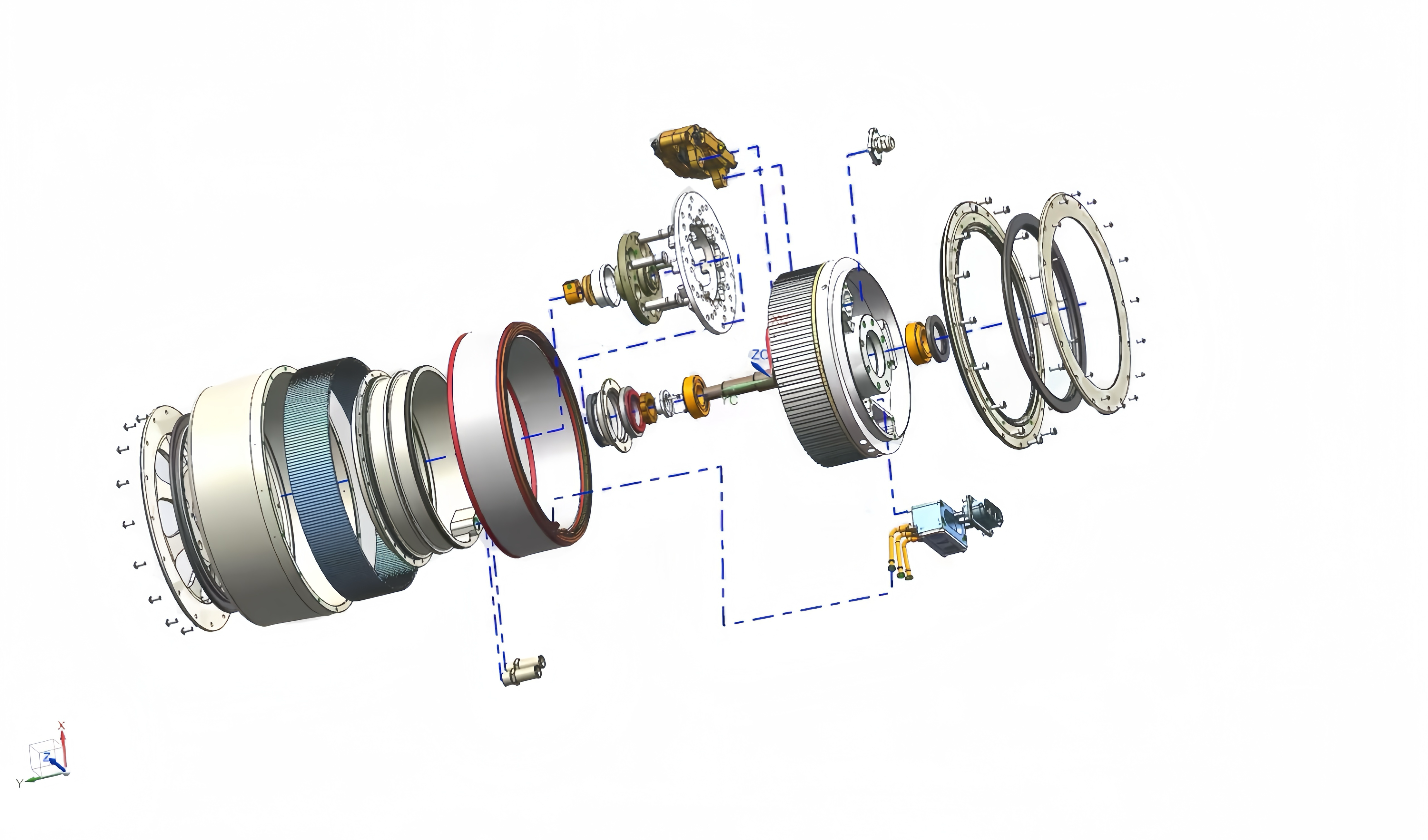

In-wheel motor, also known as in-wheel hub motor, or in-wheel engine. They are are integrated directly into the wheel hub of a vehicle. These innovative propulsion systems provide a compact and efficient solution for electric vehicles and offer several advantages over traditional drivetrains.

It consists of electric motors, control units, and wheel hubs. Compared to mid-mounted motors, the benefits of hub motors include boosting range, saving space, excellent maneuverability, enhanced safety, and suitability for autonomous driving. However, due to their high cost, they have not been widely adopted.

More about our in-wheel hub kits:

In addition to the features mentioned above, Beetle Motor focuses more on ensuring the stability and safety in the design of in-wheel hub motor.

Meanwhile, we aim to manufacture products that are suitable for mass production and offer more cost control, contributing to the wider adoption of in-wheel motor.

- Higher efficiency: Direct drive with external rotor, no need for a reducer.

- Better performance: Patented independent flat-wire winding, combined with Halbach array electromagnetic design, achieves ultra-high torque/weight ratio and lower heat generation.

- Greater safety: Passed 1200 hours of continuous operation test. Optional patented distributed arc motor structure design, which improves safety and reliability by individually controlling multiple units of the in-wheel engine.

- Excellent handling: Patented embedded kingpin structure, which realizes more flexible and agile steering.

- Space optimization: Compared with the current dual-motor drive module, it can save 300L of underbody space.

- Higher economy: Already in the pre-production stage, the more favorable cost makes the popularization of in-wheel motor more feasible.

Models of our in-wheel hub motor :

- Wide applicability: Five models of in-wheel hub motor from 12 to 20 inches are available. Suitable for two-wheel drive or four-wheel drive electric vehicles, hybrid electric vehicles, and fuel cell vehicles. Customization is also available according to needs.

| Model | 12 inches | 14 inches | 16 inches | 18 inches | 20 inches |

|---|---|---|---|---|---|

| Voltage (V) | 400 | 330 | 400 | 400 | 400 |

| Rated Power (Kw) | 20 | 40 | 40 | 70 | 75 |

| Rated Speed (rpm) | 1,200 | 750 | 850 | 900 | 700 |

| Rated Torque (Nm) | 160 | 450 | 450 | 750 | 1020 |

| Peak Torque (Nm) | 450 | 710 | 950 | 1,900 | 2,600 |

| Peak Power (Kw) | 40 | 55 | 75 | 130 | 150 |

| Peak Speed (rpm) | 1,500 | 1,200 | 1,500 | 1,400 | 1,400 |

| Efficiency (%) | 95 | 91 | 96 | 95 | 95 |

| Rotor Outer Diameter d/(mm) | 256 | 297 | 361 | 406 | 457 |

| Weight (Kg) | 28 | – | 33.5 | 52 | 64.5 |

| Cooling method | water cooling | air cooling | water cooling | water cooling | water cooling |